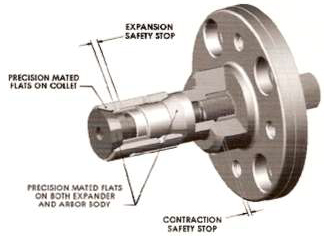

- For all styles of Ultra-Lock Arbors the collet expansion safety stop is fixed and no adjustment is required. the collet contraction safety stop is adjustable and must be set to allow for loading of part piece.

- All collets are manufactured with expansion preload. Corresponding flats on collets and arbor must be in contact during installation adjustment.

- Collets should not be readjusted below the minimum size specified for a collet range. Collet preloads are approximately 0.008″ for 0.500″ through 0.874″ diameter collets and approximately 0.015″ 0.875″ through 4.467″ diameter collets.

Collet and Arbor Assembly Installation

- Ultra-Lock Flange Style Actuated Arbor Collet Change Over

With drawbar in full forward position, remove expander with hex key wrench. Remove collet and dirt seal sleeve. Clean arbor components and lightly grease the expander, flats, shaft and the collet flats. Replace dirt seal sleeve and position collet into place with flats in contact. Install expander and adjust with hex key wrench until a low limit part piece is a slip fit on the collet. Flats on both ends of the collet must mate. - Ultra-Lock Air Operated Flange Style Arbor Collet Installation

With air pressure at 70 P.S.I., remove expander with hex key wrench. Remove collet and dirt seal sleeve. Clean arbor components and lightly grease the expander, flats, shaft and the collet flats. Replace dirt seal sleeve and position collet into place with flats in contact. Install expander and adjust with hex key wrench until a low limit part piece is a slip fit on the collet. Flats on both ends of the collet must mate. - Arbor Installation

Remove arbor mounting screws. Apply 70 P.S.I. air pressure allowing piston to move forward and turn arbor assembly counterclockwise until drawbar disengages from piston assembly. Mount new arbor assembly by turning arbor assembly clockwise until face contacts cylinder then, back off to align tapped holes in cylinder. Insert and snug mounting screws , release air pressure and tighten the mounting screws. - Ultra-Lock Between Centers Style Arbor Collet Change Over

Remove lock-nut, expander nut and expander sleeve. Remove collet and dirt seal sleeve. Clean arbor components and lightly grease expander flats, collet flats and arbor shaft. Replace dirt seal sleeve and position collet into place with flats in contact. Install expander, assemble expander nut and lock-nut. Expand collet by turning expansion nut until a low limit part piece is a slip fit on the collet, flats on both ends of the collet must mate. Turn the lock-nut with a wrench until snug against operating nut.

Recommended Drawbar Pressures

The following recommendations are guidelines, actual drawbar pressure is to be determined by customer. In any case do not exceed the maximum force listed. Excessive drawbar pressure can break expander shaft, and insufficient drawbar pressure will allow the part to move on the collet.

| Long Series | Short Series | Light Duty | Medium Duty | Heavy Duty | ||

|---|---|---|---|---|---|---|

| Catalog # | Range | Catalog # | Range | Drawbar Force Max Lbs |

Drawbar Force Max Lbs |

Drawbar Force Max Lbs |

| ULC-2110 | 0.500-0.655 | ULC-8100 | 0.500-0.655 | 1,000 | 1,500 | 2,000 |

| ULC-2210 | 0.593-0.780 | ULC-8200 | 0.593-0.780 | 1,000 | 1,500 | 2,000 |

| ULC-2310 | 0.718-0.999 | ULC-8300 | 0.718-0.999 | 1,300 | 2,500 | 3,100 |

| ULC-2410 | 0.875-1.397 | ULC8400 | 0.875-1.397 | 2,000 | 4,500 | 6,700 |

| ULC-2510 | 1.125-1.656 | ULC-8500 | 1.125-1.656 | 2,500 | 6,000 | 11,500 |

| ULC-2610 | 1.468-2.092 | ULC8600 | 1.468-2.092 | 3,000 | 10,000 | 23,000 |

| ULC-2710 | 1.937-2.843 | ULC8700 | 1.937-2.843 | 3,000 | 11,000 | 23,000 |

| ULC-2810 | 2.562-3.593 | 3,500 | 12,000 | 23,000 | ||

| ULC2910 | 3.312-4.467 | 3,500 | 13,000 | 23,000 |