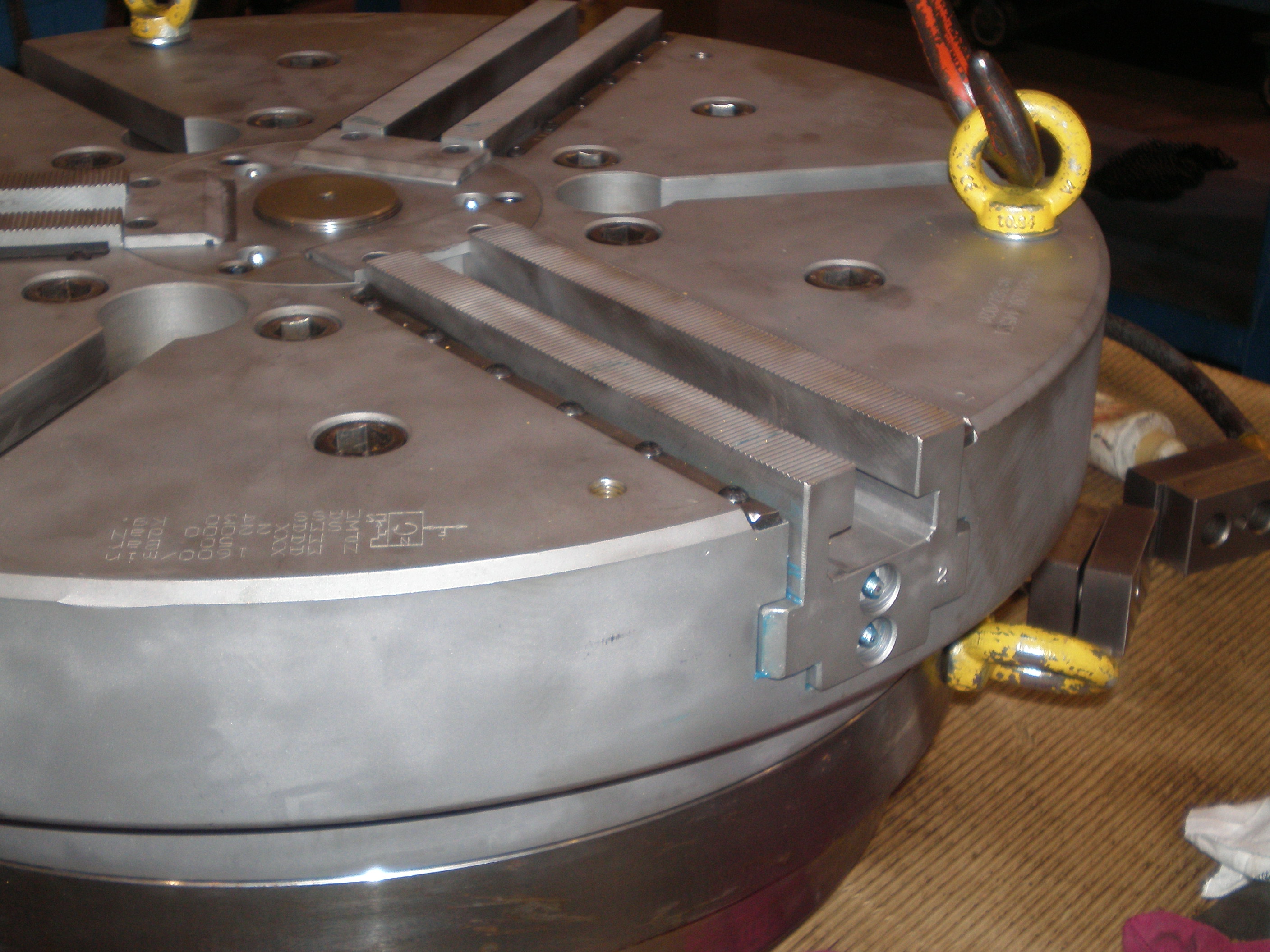

Ultra-Grip International’s experienced team of service technicians repairs and rebuilds both UGI’s and competitors chucks. Chucks overtime can fail to produce accurate parts, lose necessary grip force, and even seize due to various reasons such as wear, corrosion, and damaged components caused by wrecks.

- All repairs and rebuilds include an inspection and evaluation followed by a formal quote.

- Inspection and evaluation include dis-assembly, cleaning, visual inspection, limited dimensional inspection, and analysis and comprehensive write up to generate quote price.

Repairs

- Chucks that can be repaired by only replacing spare parts can be serviced at Ultra-Grip or at their installed facilities.

- A service call fee will be assessed for all non-warranty chucks.

- UGI’s Ball-Grip™ Pull Down Chuck have inventoried standard components which can generate a quick turn around.

Rebuilds

Chucks that require more extensive work than spare parts will have to be rebuilt at UGI’s facility.